Electric truck costs: TCO of EV and ICE

Inhaltsverzeichnis

Key facts at a glance

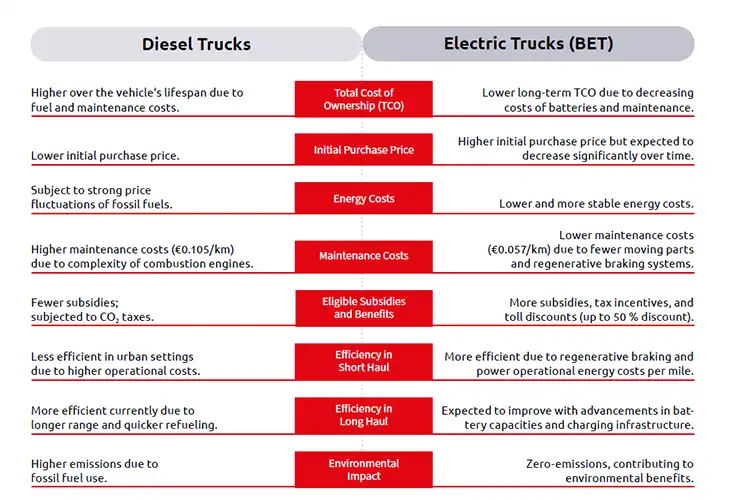

- Significant differences in initial purchase price, maintenance costs, energy costs, and depreciation between electric and diesel trucks greatly influence the total cost of ownership (TCO).

- Despite higher initial costs, electric trucks become more cost-competitive over time due to lower maintenance costs, reduced energy consumption, and favorable depreciation rates.

- Transitioning to an electric fleet supports environmental sustainability and helps fleet operators comply with EU regulations for green logistics.

Inhaltsverzeichnis

As the transportation industry transitions towards greener technologies, understanding the total cost of ownership of electric vehicles (EVs) compared to internal combustion engine (ICE) vehicles is crucial for fleet operators and policymakers. The TCO analysis encompasses various electric truck costs, including initial purchase price, maintenance costs, energy costs, and depreciation.

By examining these components, we can better understand the economic implications of adopting battery electric vehicles (BEVs) in place of traditional diesel trucks. This analysis draws on data and insights from the TNO report to provide a comprehensive comparison of these key cost elements.1

um bis zu 90 Prozent im Vergleich zu herkömmlichem Diesel.

Inhaltsverzeichnis

Initial purchase price: e-truck costs vs. diesel truck costs

The initial e-truck price is a significant factor affecting the total cost of ownership. According to the TNO report, the upfront costs for battery electric vehicles) are currently higher compared to diesel trucks, primarily due to the high costs of batteries and fuel cell systems. In 2020, the pre-tax retail price for a medium BEV rigid urban truck was approximately 147,000 Euro, compared to 79,000 Euro for its diesel counterpart. Similarly, an articulated regional BEV truck had a pre-tax price of 355,000 Euro, whereas the equivalent diesel truck was priced at 144,000 Euro.

However, these electric truck costs are expected to decrease significantly over time due to advancements in technology and increased production volumes. By 2030, the pre-tax retail price of a medium BEV rigid urban truck is projected to drop to 88,000 Euro, which is comparable to the projected price of 87,000 Euro for a diesel truck. The articulated regional electric truck price is expected to reduce to 183,000 Euro by 2030, while the diesel truck's price increases to 159,000 Euro. This trend continues into 2040, with further price reductions for BEVs and a stabilization of prices for diesel trucks.

The initial high costs of BEVs are largely due to the expenses associated with their advanced components, particularly batteries and fuel cells. For instance, battery costs are influenced by the energy density and the type of battery chemistry used, which is expected to improve and become more cost-effective over time. The integration of battery cells directly into the vehicle chassis is one such development that will contribute to cost reductions.

Das Wichtigste in Kürze

- Eine schnelle Ausweitung des Ladeinfrastrukturnetzes ist erforderlich, da immer mehr E-Lkw zum Einsatz kommen.

- Milence entwickelt in Partnerschaft mit UTA Edenred ein spezialisiertes Netzwerk von Schnellladestationen für schwere Fahrzeuge in Europa.

- Verschiedene Arten von Schnellladestationen (bis zu 400 kW) sind notwendig, um die Ladezeiten zu verkürzen und die Einsatzbereitschaft von Elektro-Lkw-Flotten zu verbessern.

Maintenance costs of e-trucks compared to diesel trucks

Maintenance costs are a significant factor in the TCO for electric and diesel trucks. For diesel trucks, maintenance costs are traditionally higher due to the complexity of internal combustion engines and the numerous moving parts that require regular servicing and replacement. These electric truck costs include oil changes, engine tuning, exhaust system maintenance, and frequent replacement of components such as filters and spark plugs. Additionally, diesel engines are subject to wear and tear from combustion by-products, leading to more frequent repairs and part replacements over the vehicle's lifetime.

In contrast, battery electric vehicles have significantly lower maintenance costs. The TNO report states that BEVs benefit from having fewer moving parts and a simpler drivetrain. Key components such as the electric motor and battery require less frequent maintenance compared to ICEs. There is no need for oil changes or exhaust system maintenance, and regenerative braking systems reduce wear on brake pads and rotors, extending their lifespan. As a result, the TNO report estimates that maintenance costs for BEVs can be up to 50 percent lower than those for diesel trucks.

Comparison of energy costs of e-trucks and diesel trucks

The energy costs for electric and diesel trucks exhibit significant differences that influence the total cost of ownership for these vehicles. According to the TNO report, diesel prices are closely tied to crude oil prices. The average oil price over the past decade was approximately 70 Euro per barrel in 2020, with projections indicating fluctuating prices influenced by geopolitical factors and economic policies. The crack spread, or the difference between crude oil purchase and diesel selling prices, further affects the diesel cost, making diesel relatively cheaper on a per-unit energy basis in the short term.

In contrast, electricity prices are composed of production, distribution, and infrastructure costs. The TNO report notes that the average electricity prices in the EU+UK for non-household consumption bands indicate a higher cost per kWh compared to diesel. However, this is mitigated by the significantly lower energy consumption rates of battery electric vehicles (BEVs). Depot charging infrastructure costs add approximately 0.047 Euro per kWh, while fast charging infrastructure can add up to 0.096 Euro per kWh by 2030, decreasing slightly thereafter. These costs, when combined with higher efficiency rates, make the energy cost per kilometer for BEVs lower than diesel vehicles by a factor of 1.1 to 3.3 by 2030, and 1.4 to 3.5 by 2040.

Depreciation of EV and ICE

Depreciation is a critical component of TCO for e-trucks and diesel trucks. According to the TNO report, depreciation rates significantly impact the economic feasibility of different drivetrain technologies.

For diesel trucks, the depreciation rate is relatively stable and predictable. The TNO report assumes a fixed depreciation rate of 7.5 percent per year, resulting in a 37.5 percent depreciation after five years. Additionally, there is a variable depreciation component based on the mileage of the truck. A vehicle has no residual value after reaching a lifetime mileage of 1.49 million kilometers, which translates to an average daily mileage of 1150 kilometers over five years. This linear depreciation model estimates the residual value ranging from 61 percent at 25 km/day to 8 percent at 1000 km/day.

BEVs follow a similar depreciation structure but are influenced by different factors. BEVs, in particular, are subject to depreciation influenced by battery degradation and technological advancements. As battery technology improves and becomes more cost-effective, the residual values of BEVs are expected to stabilize. The TNO report indicates that the fixed depreciation rate for BEVs is also 7.5 percent per year, but the variable rate can be influenced by the perceived longevity and reliability of battery systems.

Summary: how do the cost of electric trucks compare with diesel trucks?

- Initial purchase price: Although the initial purchase price of electric trucks is currently higher than that of diesel trucks, substantial reductions in battery and fuel cell costs over the next two decades are expected to narrow this gap. These advancements will make BEVs increasingly cost-competitive.

- Maintenance costs: The TNO report concludes that the reduced maintenance costs of BEVs significantly contribute to their lower overall operating costs compared to diesel trucks. This cost advantage, combined with lower energy costs and higher efficiency, makes electric trucks a more economically viable option for the future of freight transport.

- Energy costs: While diesel trucks benefit from lower initial energy costs, the higher efficiency and lower energy consumption of battery electric vehicles contribute to lower electric truck costs in the long term. As energy prices rise, the cost advantage of BEVs becomes more pronounced.

- Depreciation: While diesel trucks have a well-established depreciation model, the depreciation rates for BEVs are evolving as technological advancements and market acceptance improve. The TNO report provides a comprehensive view of how these factors contribute to the overall TCO, highlighting the economic potential and challenges associated with the transition to zero-emission trucks.